We pride ourselves on our expertise, our proactive approach and our ability to consistently exceed the expectations of our customers

Technical

With press ranges from 50 ton to 850 ton, Boddingtons has vast capability targeting the correct process for each tool individually. The flexibility doesn’t stop their, with a range of tie-barless machines offering very large platen sizes allowing for larger tools in a smaller press size range.

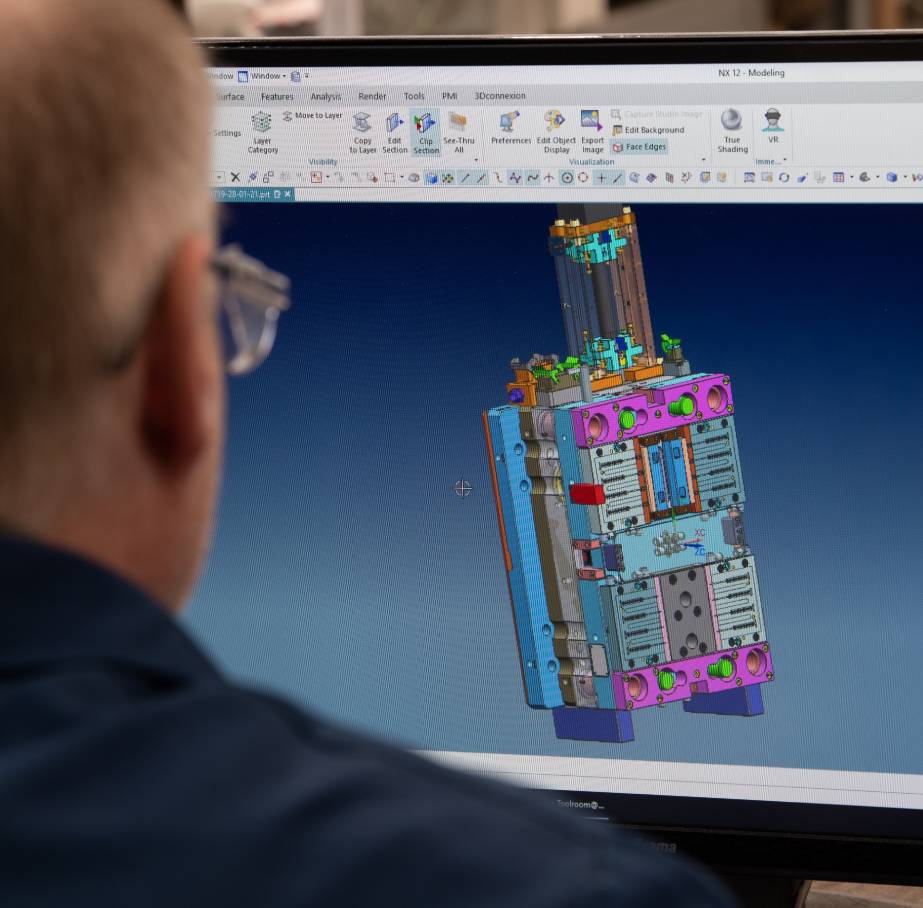

It’s critical our engineers enter the DFM stage as early as possible to feed into the customers design component

Every step of the process is mapped out & shared to ensure the tooling meets the requirements for the product it’s designed for, including the machine types and sizes chosen for production

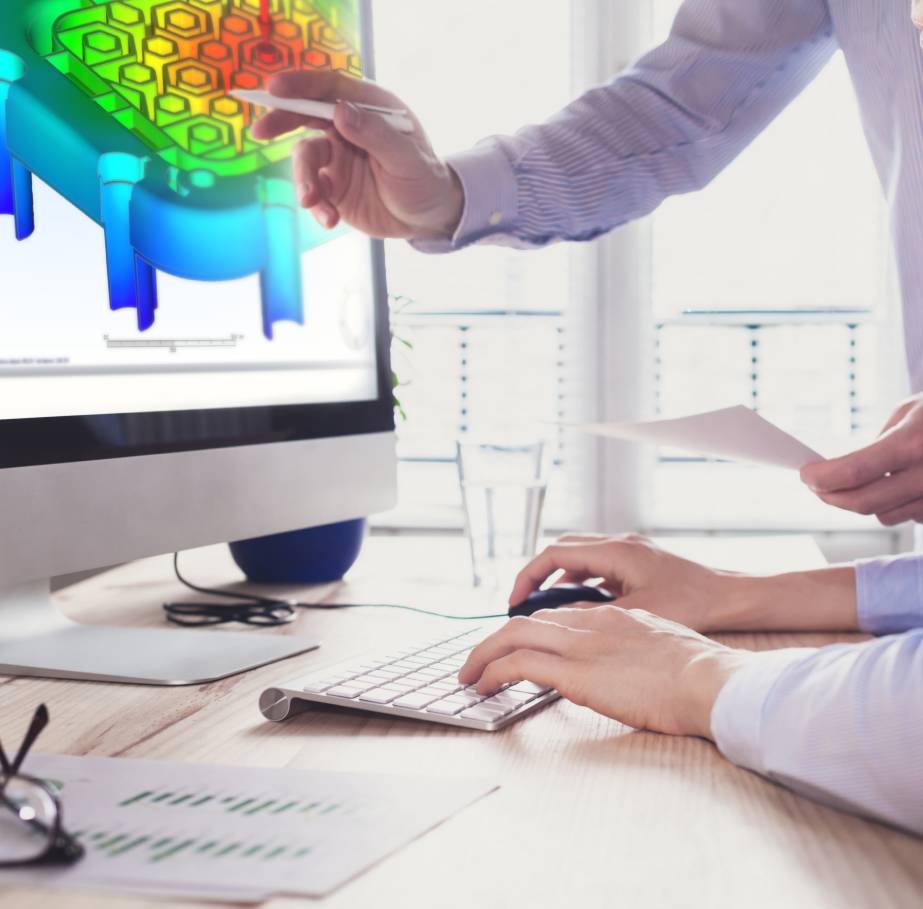

Before any steel is ordered for the tool build, the tool design can be challenged through moldflow simulation to ensure that potential problems are highlighted and dealt with appropriately

Making sure the tooling is fully functional before it leaves the Toolmaker is key, following a number of basic steps and running the tool at production rates over a set period

Replicating exactly what was seen in the FAT – at Boddingtons the tool is put through its paces and optimised to meet the product specification

Working to a fully documented and agreed protocol, the validation process confirms that the tooling offers the highest product quality meeting specification and capability

Designing Products for Tool Manufacture can be a complex process. At Boddingtons, we have a wealth of experience working to extremely tight tolerances, supporting customers on the tooling limitations from a product design, but importantly designing Quality into the product from the ground up.

Using the latest technology, Moldflow enables Boddingtons and the Customer to see the affects of the product from the tool design before steel is even cut Gate positioning, Weld lines, Venting, Distortion and Warpage are just a few areas that the software can help show potential issues so they can be address together.

Having a point of contact from the outset is important for both Boddingtons and customer as we partner together to hit the agreed timelines. Using key milestones throughout the process ensures that the activities and time needed to complete are communicated to all parties at every step of the way

-

Material Processing

From polypropylene, polycarbonates to high glass content nylons including PEEK

-

Fully Flexible Production Press Availibility

From 50 ton to 850 Ton presses including Tie-barless machines

-

Shop Floor Data Collection

Using the latest software technologies, linked to every machine, Boddingtons is able to monitor machine utilisation and efficiency to maintain